High-Speed-Steel Makes Resurgence in Drilling and Broaching

Why Using High-Speed Steel is Cool Again in Hole Making, or did it ever go away?

Introduction:

The world of working metalworking is complex, with many solutions for any project. In this blog, I will focus on drilling and broaching, and talk about a tooling material that’s making a comeback – high-speed steel (HSS). While newer and harder alloy materials have been introduced in recent years, HSS is quietly maintaining its place in the spotlight. So, let’s explore why using HSS is cool again in some applications:

1. What is HSS?

It is a type of tool steel known for its exceptional durability, as well as its ability to withstand high temperatures. HSS is composed of various elements, including tungsten, molybdenum, chromium, and vanadium, which give the material its heat resistance and wear properties.

2. Why is HSS Gaining in Popularity? Versatility and Cost-Effectiveness.

One of the main reasons for the resurgence in HSS usage is its versatility. HSS tools can handle a wide range of materials, including stainless steel, carbon steel, and non-ferrous metals.

Moreover, HSS tools are cost-effective compared to their carbide counterparts, and provide an ideal balance between performance and affordability (to buy and/or re-sharp over time), making them a practical choice for many applications.. In contrast, carbide tools offer exceptional performance, but they usually come with a higher price tag, not just to buy, but also to re-sharp.

3. What about Heat Resistance and Toughness?

In machining applications, interrupted cuts, along with heat and friction, are “enemies” that can quickly wear down cutting tools. In those situations, HSS tools shine. Thanks to their combination of hardness, wear resistance, and heat resistance, HSS tools can withstand tough conditions without dulling too quickly. That feature means HSS tools can work longer without having to be changed or re-sharpened.

Furthermore, HSS tools possess remarkable toughness, which helps them absorb shocks and vibrations during machining. This resilience makes HSS tools less prone to chipping or breaking, extending their lifespan, and saving you money in the long run.

4. What are Some Proven Applications for HSS Tools?

Because of its versatility, cost effectiveness, heat resistance, and toughness, HSS is still the material of choice for broaching, drilling, and tapping. In fact, for many applications, HSS is the only material that can work effectively. Many tooling manufacturers have launched new products with other materials, but their efforts haven’t been successful.

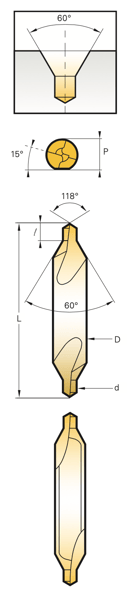

When it comes to holemaking applications, we find that HSS is highly effective in spot drills, center drills, reamers, countersink, and counterbore tools. The use of HSS in those kinds of tooling is primarily cost-driven choice, but we recently discovered that certain tools made of HSS can do an outstanding job of working on hard metals. For example, many OEMs and tier manufacturers in aerospace and defense prefer to use HSS for their applications. At times, it is the only carbide alternative that works.

For example, HSS is ideal for countersinks that create V-channels for rivets used in the production of aerospace parts and components, including door frames, landing gear, and other parts such as cast titanium forgings, which require high structural integrity.

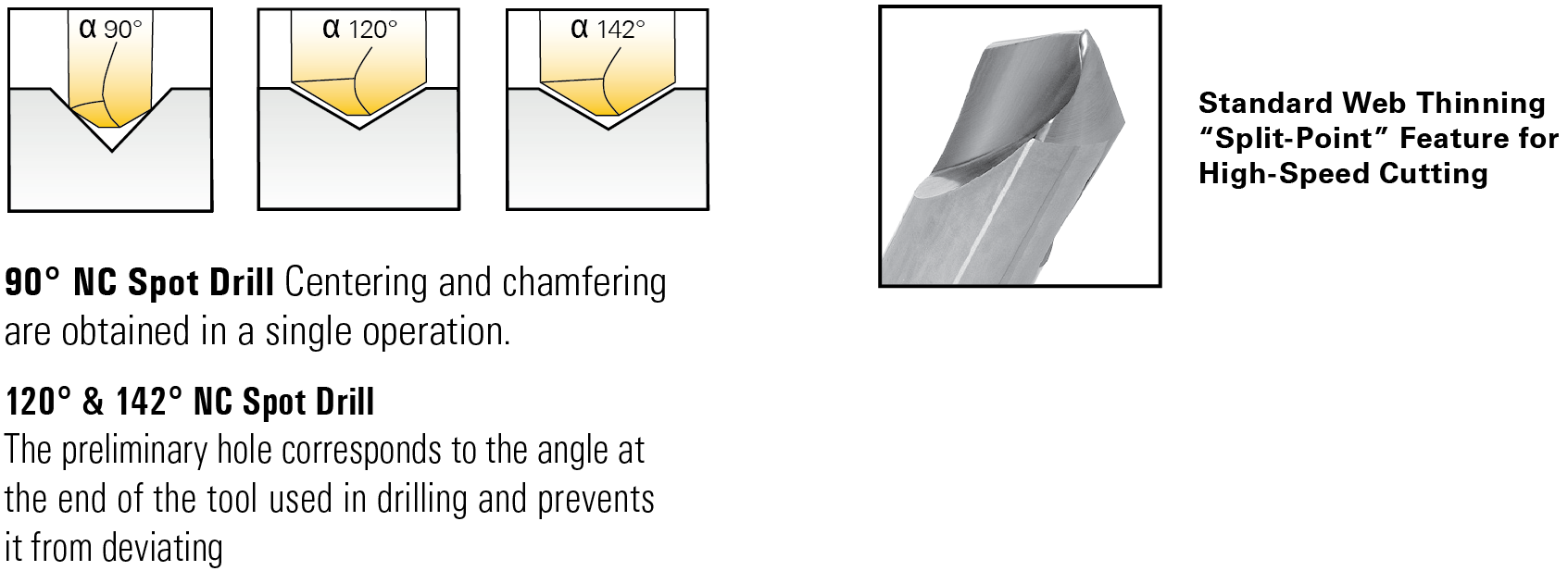

To maximize efficiency, centering and chamfering can be achieved in a single operation and at an angle that prevents the tool from deviating. What’s more, drills with a web-thinning “split-point” feature allow HSS tools to penetrate material surfaces and reduce the potential of walking in different materials.

Conclusion:

Just as vinyl records are making a comeback because of their sound quality, HSS tools are enjoying a similar revival.

Just as vinyl records are making a comeback because of their sound quality, HSS tools are enjoying a similar revival.

In a variety of holemaking and broaching applications, HSS is the best way, if not the only one. That’s because HSS is typically one-third the cost per tool, when compared to the alternatives. With the ability to operate at slower speeds, HSS tools can withstand the punishment that would cause carbide tools to break, making HSS ones more forgiving, and for some applications, tough to beat.

In my experience, Magafor precision HSS tooling is ideally suited for applications involving hard metals and exacting specifications. As the world’s leading manufacturer of center and spot drills, Magafor supplies customers with 4 million of them a year. The company has invested in state-of-the-art machinery, and as a result, its drills are highly effective due to their unique ground spiral flutes, as well as the concentricity of the drill diameter to the body, which makes Magafor HSS drills better suited than alternatives to a wider range of applications.

To discuss your specific requirements:

-1.png)